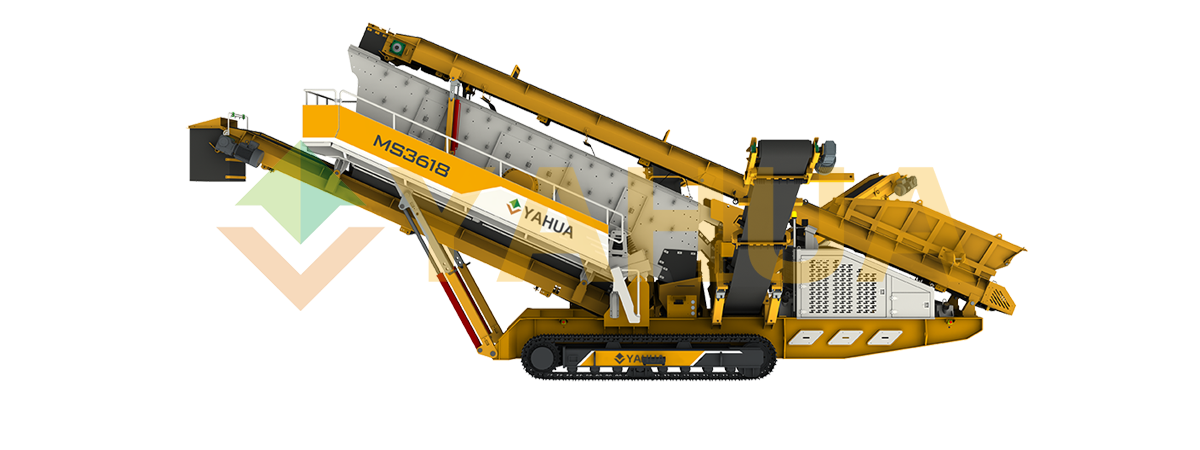

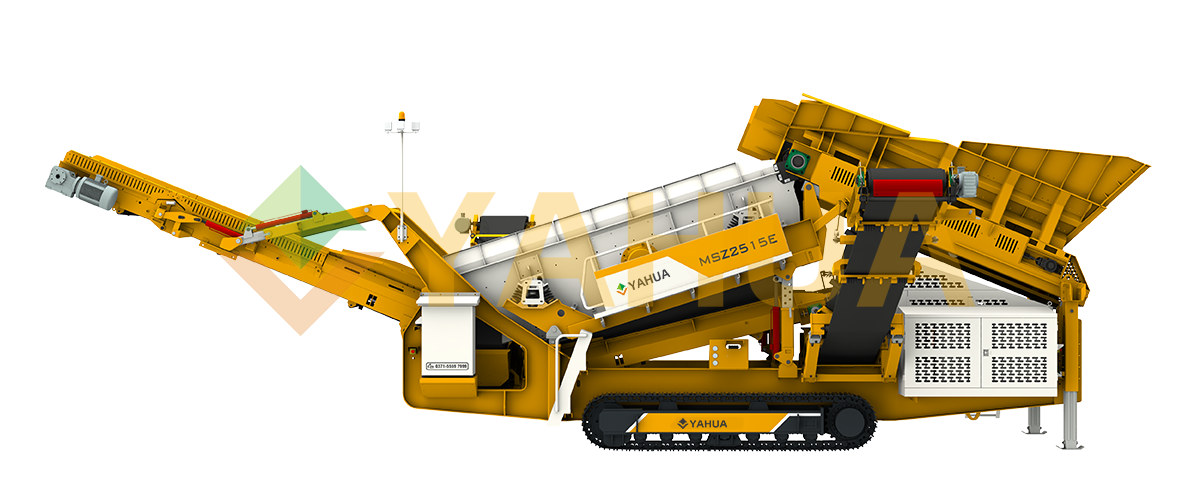

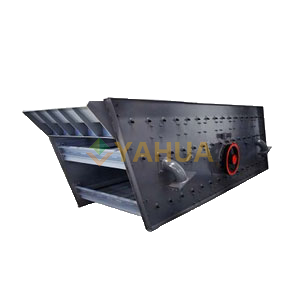

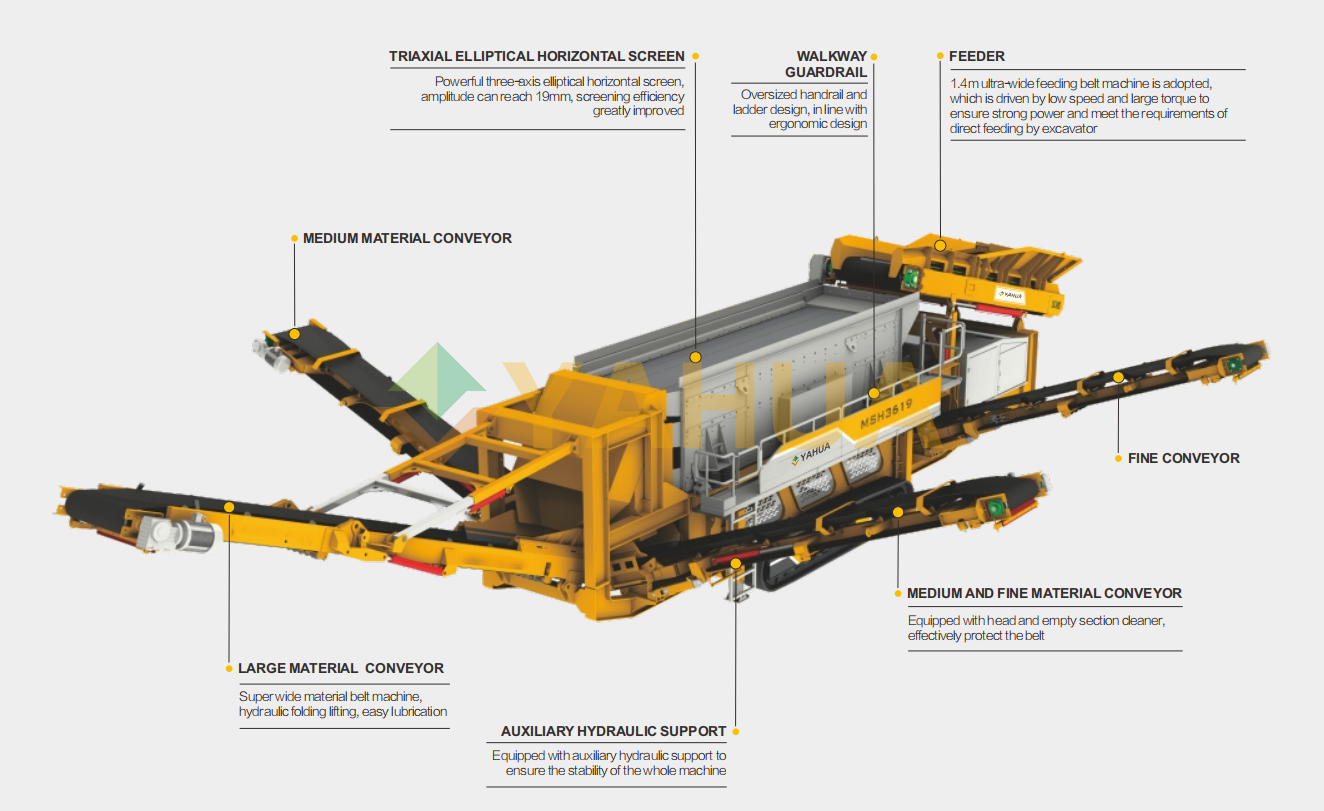

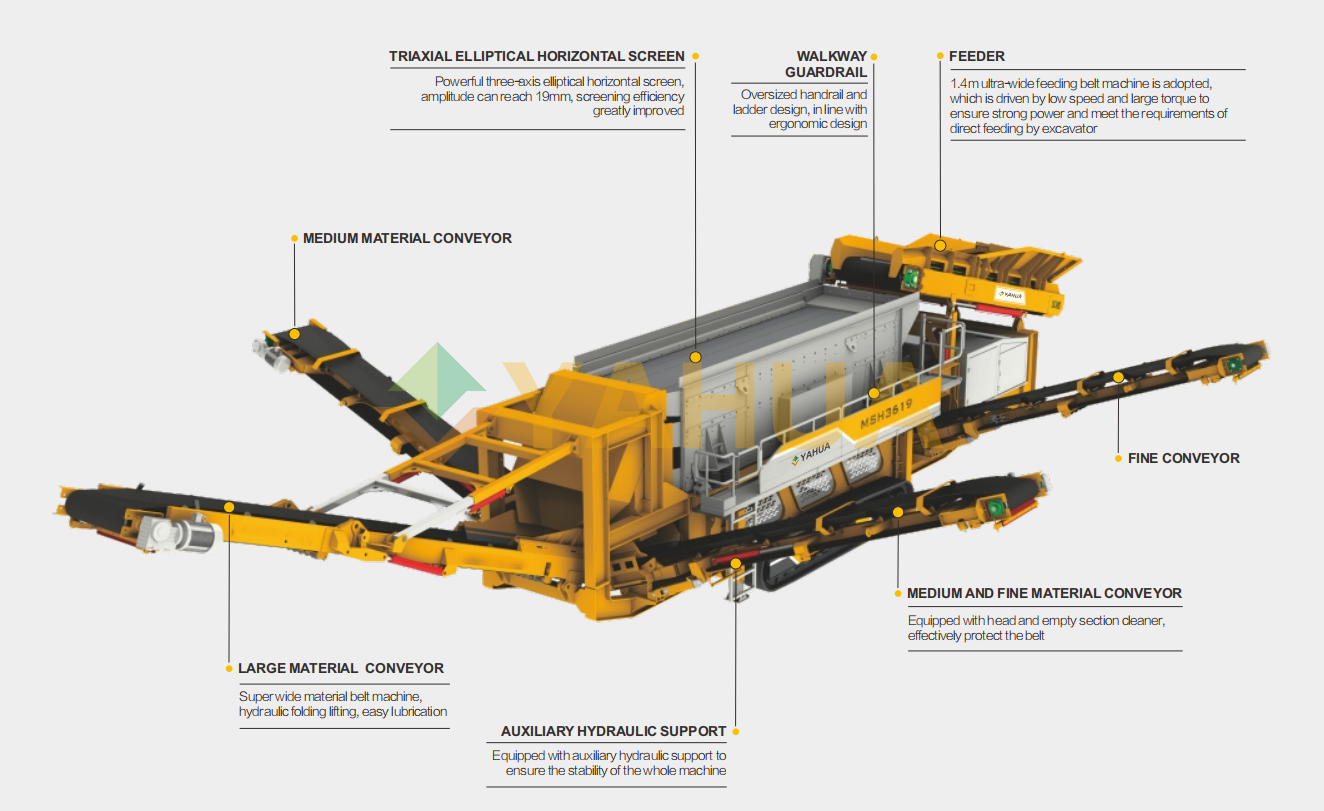

MSH Series Tracked Mobile Horizonal Screening Station adopts a three-axis horizonal screen as the main equipment, which is driven by three axes and has an elliptical vibration trajectory. It has good screening performance, high screening accuracy, large capacity, low installation height.

MSH is equipped with a high torque and slow rate feeder, ensuring uniform feeding and it has better screening performance in sticky materials.

The whole machine has a wide range of applications, high intelligence, simpler operation, convenient transfer, high screening efficiency, and can choose from three power modes: external power supply, gas-electric hybrid, and full hydraulic drive.

Speed(km/h)

Speed(km/h)