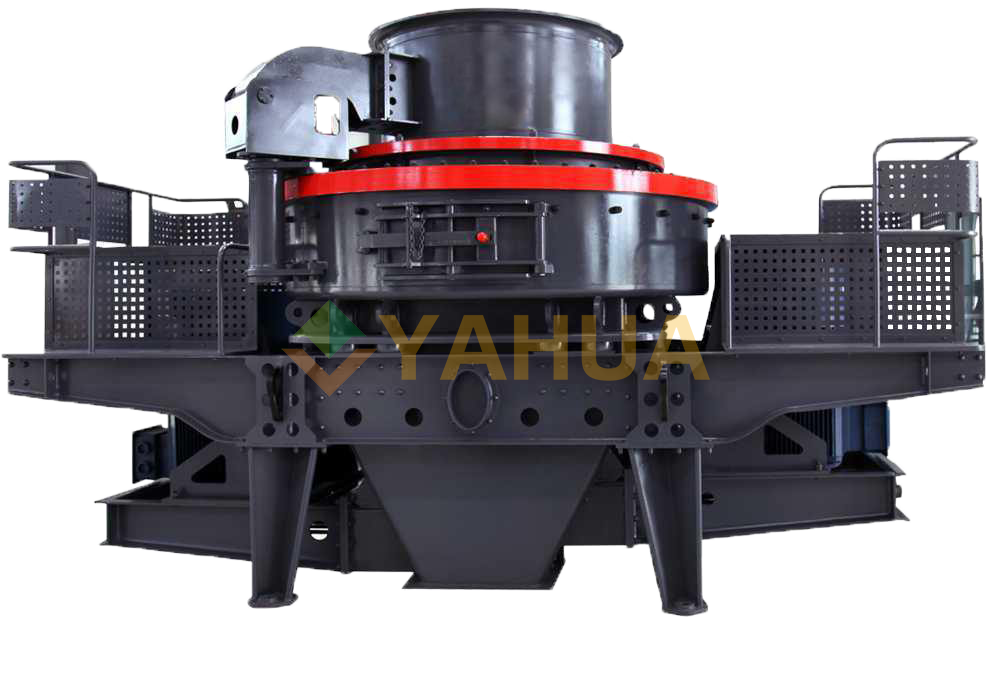

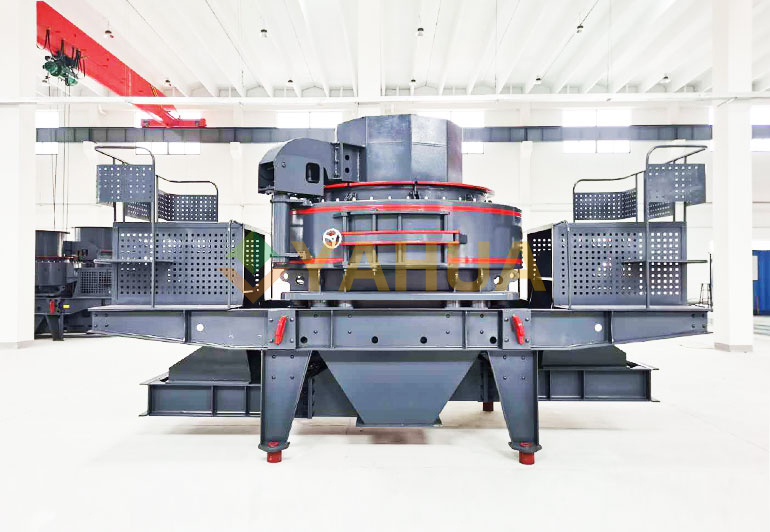

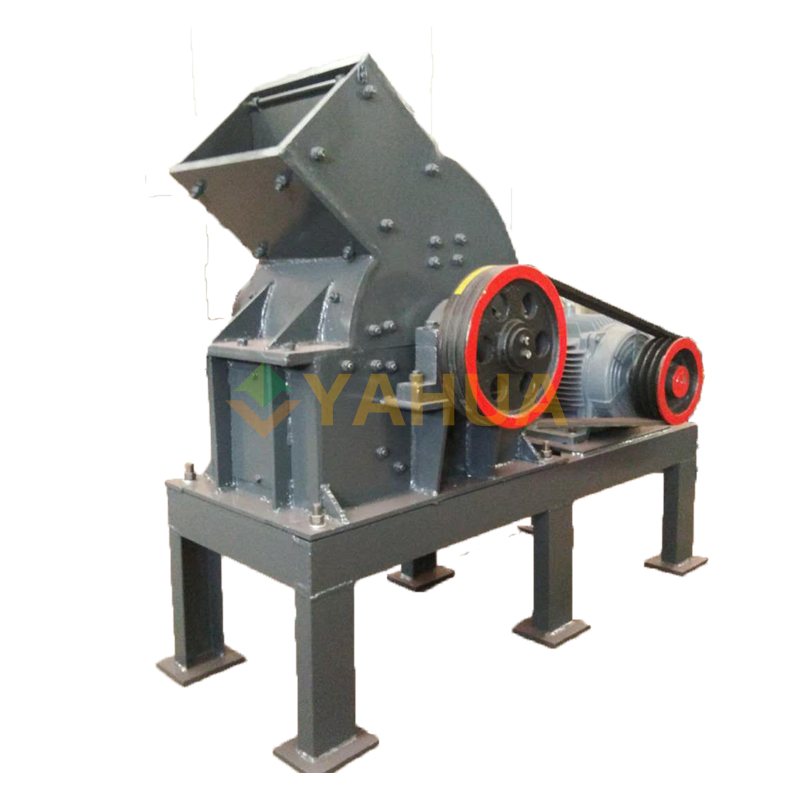

VSI sand making machine is also called vertical shaft impact crusher. It can make various rocks, gravel, river stone into construction sand . The sand has uniform particle size and high compressive strength. It is much more in line with construction requirements than the sand produced by ordinary hammer crusher and can improve the quality of construction. The equipment has the characteristics of reliable performance, reasonable design, easy operation and high working efficiency.

【capacity】:60-520t/h

【input size】:<50mm

Application

It is suitable for crushing raw materials in metallurgy, construction, road construction, chemical and silicate industries.

Applicable materials:

River stone, quartz, limestone, coal, basalt, granite, etc.

Features:

1. Excellent product shape

The product is cubic, with good shape, reasonable grading and adjustable fineness modulus; it is particularly suitable for artificial sand making and stone shaping. Practice has proved that the sand making and shaping effects are 30% higher than those of other traditional equipment.

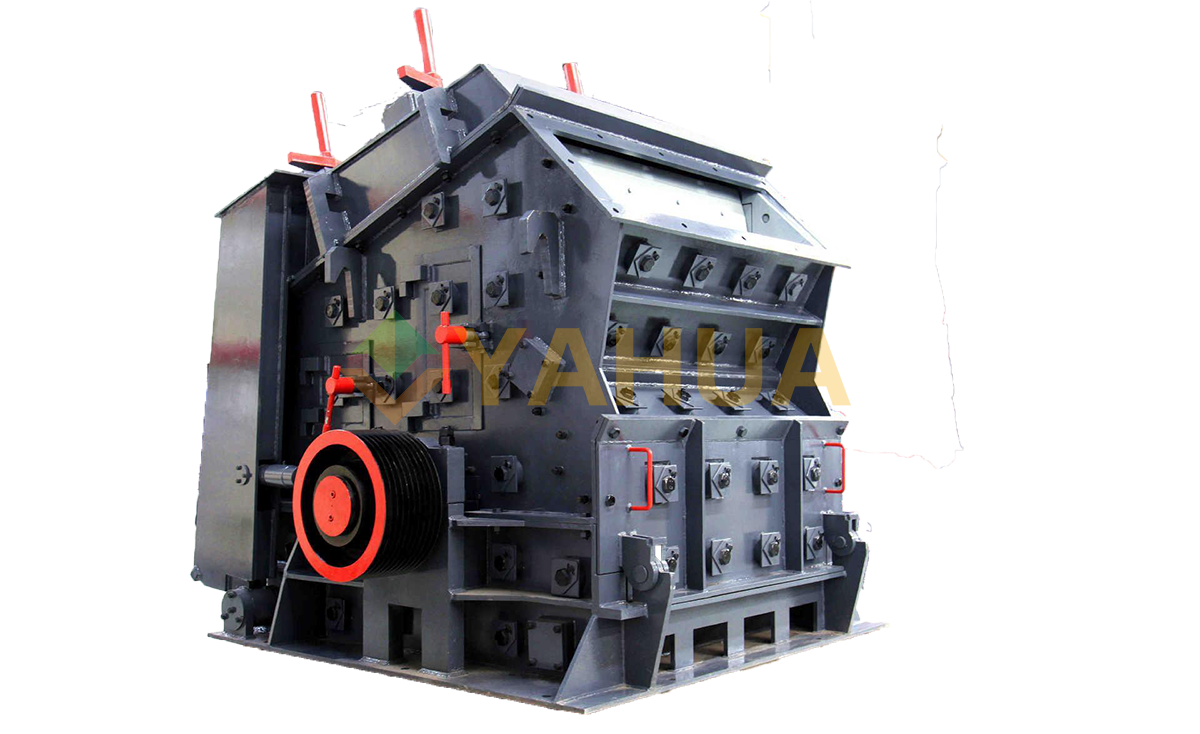

2. Low consumption of wearing parts

The good impact angle design of the crushing chamber material reduces the friction with the wear-resistant parts, which is 30% lower than the operating cost of traditional equipment, directly reducing the cost of equipment use.

3. Automatic detection, safe and reliable

The vibration display and alarm device is set. If the equipment fails to operate properly, a warning can be issued to stop the equipment from working, so as to achieve the purpose of protecting the machine.

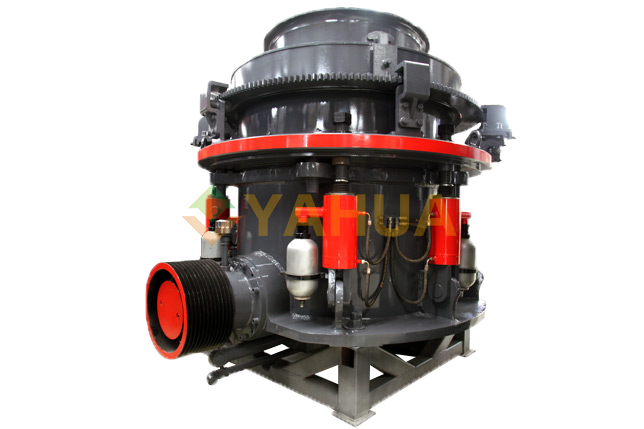

4. Hydraulic device, easy maintenance

The hydraulic cover opening device makes the inspection and replacement of the components in the crushing chamber convenient and quick, shortens the downtime, and saves time and effort.

5. Easy installation and easy operation

The equipment is light in weight, has various installation methods, and can be installed in a movable manner; it is simple to install, repair and maintain, and easy to operate; once the specific purpose is clear, the VSI crusher only needs to make minor adjustments to maximize its excellent performance.

6. Thin oil lubrication, automatic maintenance

The oil lubrication station, dual oil pumps complement each other to ensure oil supply, automatically shut down when there is no oil flow or oil pressure; the oil cooling and heating device ensures that the bearing lubrication is always in the best state. This completely solves the problem of bearing heating, keeps the spindle bearing at a constant temperature, and extends the maintenance cycle and service life.

7. Large processing capacity and high output

50-500t/h, compared with traditional equipment at the same power, the output is increased by 30% and stable.

Working principle:

VSI sand making machine uses high-speed rotating materials to break each other and the friction between materials to break