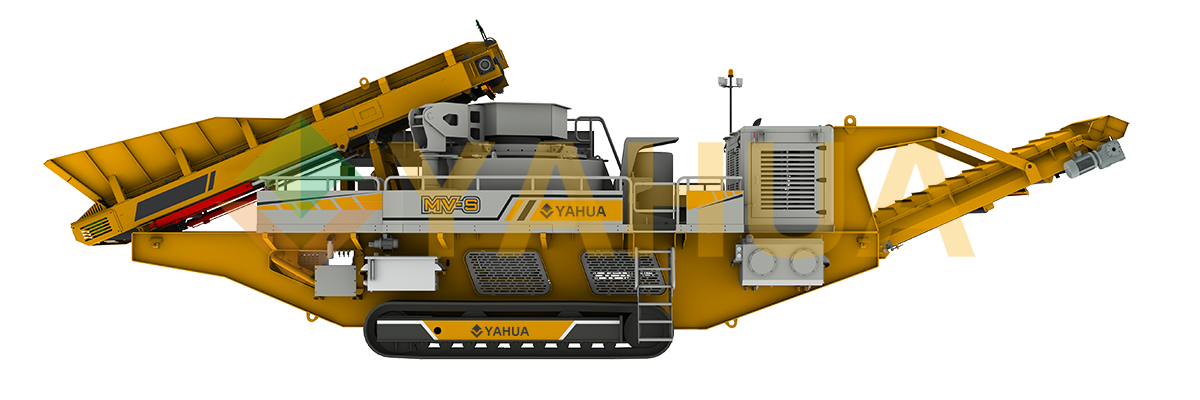

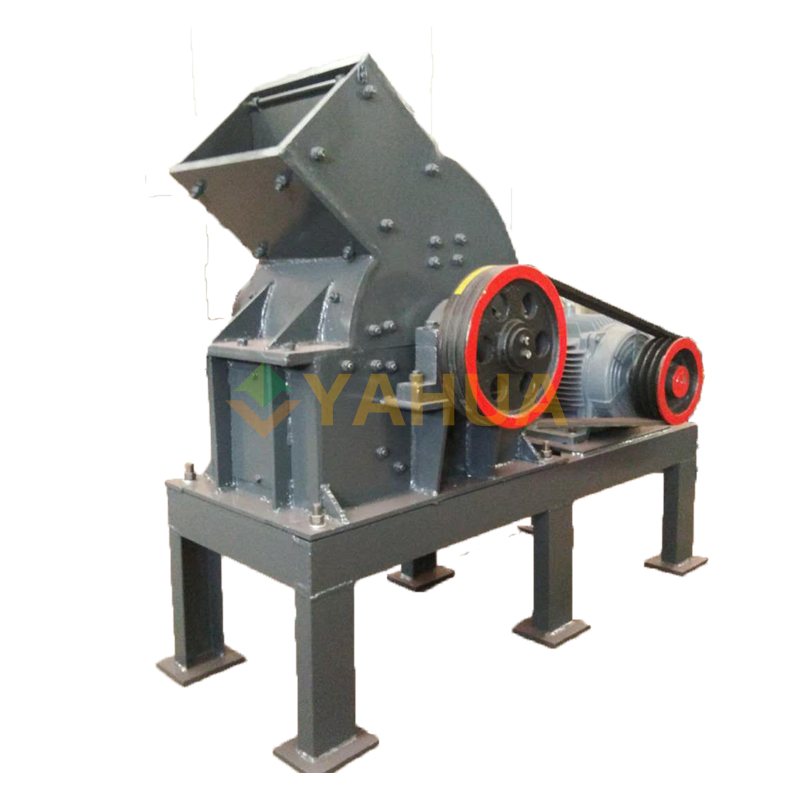

The main types of jaw crushers include PE coarse jaw crusher, PEX fine jaw crusher, PEW European version jaw crusher and other models. Jaw crusher is commonly known as jaw crusher. The jaw crushers produced by our company are mainly steel plate casting and other types. The crushing chamber is composed of two jaw plates, the movable jaw and the static jaw. The material is crushed under the extrusion of the movable jaw and the static jaw. Jaw crushers are currently widely used in quarries, mining manufacturing, building materials, roads, railways, water conservancy and chemical industrya, construction waste treatment and other industries to crush various ores and bulk materials. The maximum compressive strength of the crushed material is 320Mpa.

【Capacity】:5-800(t/h)

【Feeding size】:125-1020(mm)

【Output size】:10-300(mm)

Application Areas:

Widely used in mining, metallurgy, building materials, highways, railways, water conservancy, chemical industry and other industries

Adaptable materials:

Suitable for fine and ultra-fine crushing of hard rocks, ores, slag, refractory materials, etc.

Features:

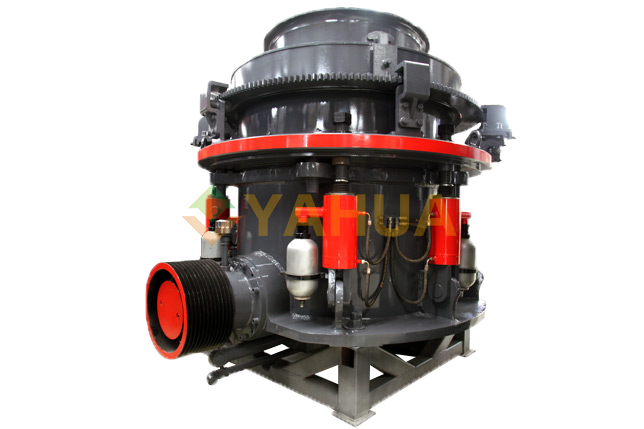

1. Hydraulic control, easy cavity cleaning

Equipped with a hydraulic oil station to ensure that the machine's lubrication system supplies oil to the machine's lubricated parts, providing protection for the machine's safe operation. At the same time, if the crusher stops under load, the hydraulic cavity cleaning system can quickly clean the crushing cavity, greatly reducing downtime.

2. Structural V-shaped toothed guard plate

The "V"-shaped crushing chamber and toothed guard plate are more reasonably designed to ensure the consistency between the actual feed size and the theoretical feed size, effectively increase the crushing area, and prevent material blockage in the crushing chamber, thereby maximizing the crushing rate and output and improving the utilization rate of the jaw plate.

3. Wedge device, quick adjustment

The wedge block discharge opening adjustment system is adopted, so that the discharge opening can be adjusted to the preset value within a few minutes even when the machine is idling. With the cooperation of the hydraulic system, it can be automated, which is simpler, safer and faster than the old gasket type discharge opening adjustment system.

4.Stable structure and reliable performance

The bearing seat adopts an integral cast steel structure to avoid the unnecessary burden of the two-piece bearing chamber on the frame and improve the stability of the whole machine structure. In addition, the heavy eccentric shaft is processed by forging billet, which makes the PEW series jaw crusher have extraordinary reliability.

Working Principle

During the operation of the jaw crusher, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone rotates and swings under the force of the eccentric sleeve. The section where the moving cone is close to the static cone becomes the crushing chamber, and the material is crushed by multiple squeezing and impacts of the moving cone and the static cone. When the moving cone leaves this section, the material that has been crushed to the required particle size falls under its own gravity and is discharged from the bottom of the cone.