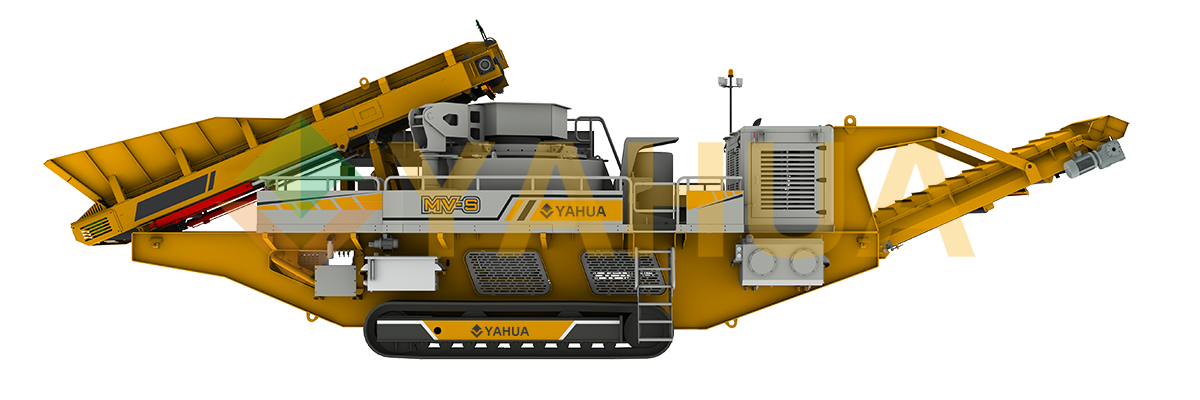

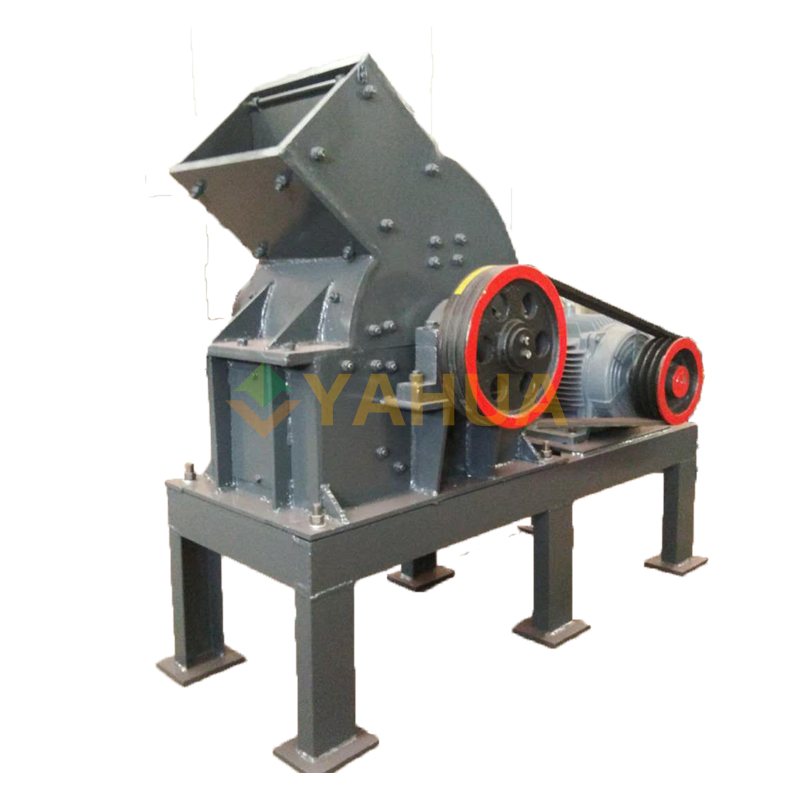

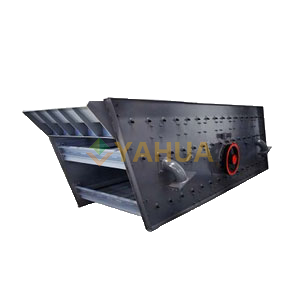

In the production process, GZD vibrating feeder can feed block and granular materials from the hopper to the receiving device evenly, regularly and continuously. In the stone crushing plant, it can feed the crusher continuously and evenly and perform coarse screening of the materials. It is widely used in the crushing and screening combined equipment in the metallurgy, coal mining, mineral processing, building materials, chemical industry, abrasive and other industries.

【Capacity】:30-1000t/m

【Input size】:300-800mm

【Power】:3-30kw

Application:

Widely used in crushing and screening equipment in metallurgy, coal mining, mineral processing, aggregate, construction waste recycling, building materials, chemical industry, abrasives and other industries

Applicable materials:

River stone, granite, basalt, quartz, iron ore, limestone, etc.

Features:

1. High efficiency and low operating cost

Double eccentric shafts are used as the excitation source, and the amplitude is stable, which ensures the fluidity of the vibrated ore material and reduces the phenomenon of channel blockage and material punching, so it has large ore drawing capacity and high efficiency; it has a simple structure, no rotating parts, and few wearing parts. Vibration consumes less power and saves significant energy.

2. Low noise and no pollution

The machine has low operating noise and can adopt a closed structure body to prevent dust pollution.

3. High adaptability and low investment

It has strong adaptability to various mineral rocks, especially viscous mineral rock materials, and can work in dusty or water-rich environments; it is small in size, light in weight, simple and compact, requires less investment, and is cost-effective.

4. Stable performance and reliable operation

The machine has good continuity and adjustable excitation force; the electrical control adopts half-wave rectifier electrical appliances, which can stepless adjust the feeding amount. It can be used in the automatically controlled production process to realize the automation of the production process.