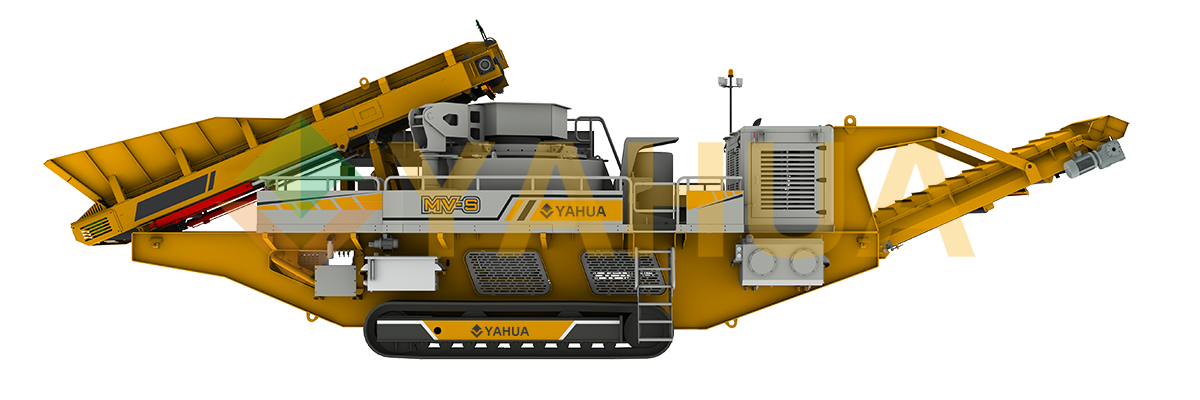

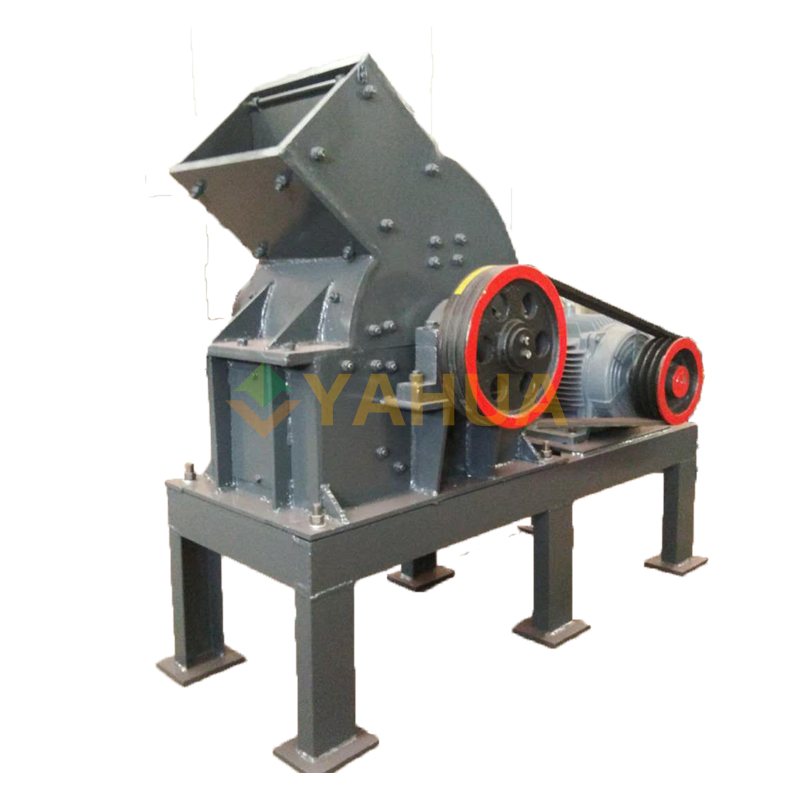

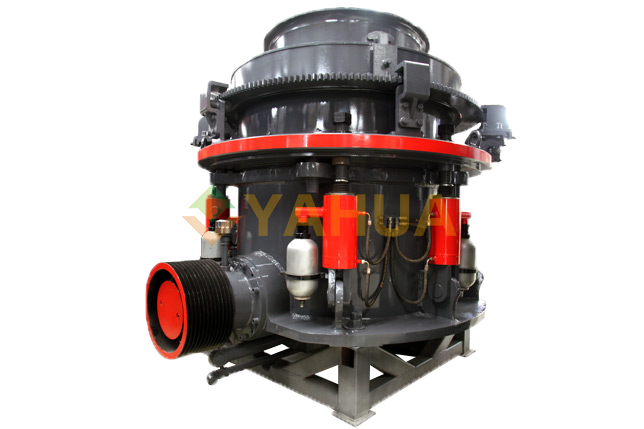

Cone crusher is suitable for crushing raw materials in metallurgy, construction, road construction, chemical and silicate industries. According to different crushing principles and different product particle sizes, it is divided into many models. Crusher is widely used in many departments such as mining, smelting, building materials, highways, railways, water conservancy and chemical industries. Cone crusher has large crushing ratio, high efficiency, low energy consumption, uniform product particle size, suitable for medium and fine crushing of various ores, rocks

【Capacity】:5-750(t/h)

【Feeding size】:35-300(mm)

【Output size】:3-51(mm)

Application Areas:

It is used in medium and fine crushing and fine crushing operations in metallurgy, mining, chemical industry, cement, construction, refractory materials and ceramics industries.

Adaptable materials:

Especially suitable for crushing chrome ore, basalt, granite and other medium and high hardness brittle materials

Equipment Features:

1. Safe and stable operation

The use of circular arc bevel gears makes the equipment run more stably, with less noise and higher transmission efficiency; hydraulic protection, the crushing chamber automatically resets after overload

2. Ease of use

The size of the discharge port can be adjusted hydraulically, which is convenient for remote control of the product particle size, saving labor and trouble; the wearing parts can be easily replaced, which completely gets rid of the trouble of packing when replacing the wearing parts of the spring cone crusher.

3. Large output

The perfect combination of stroke, swing frequency and crushing chamber shape makes the output of this machine more than 40% higher than that of spring cone crusher; high swing frequency, large stroke and high energy input, the material is crushed in layers in the crushing chamber, and the cubic content in the product is significantly increased.

4.Strong load-bearing capacity

The main shaft is supported at both ends, which can withstand greater crushing force and larger stroke.

Working Principle

During the operation of the cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device. The moving cone rotates and swings under the force of the eccentric sleeve. The section where the moving cone is close to the static cone becomes the crushing chamber. The material is crushed by multiple squeezing and impacts of the moving cone and the static cone. When the moving cone leaves this section, the material that has been crushed to the required particle size falls under its own gravity and is discharged from the bottom of the cone. The material to be crushed is loaded into the feed port of the cone crusher.