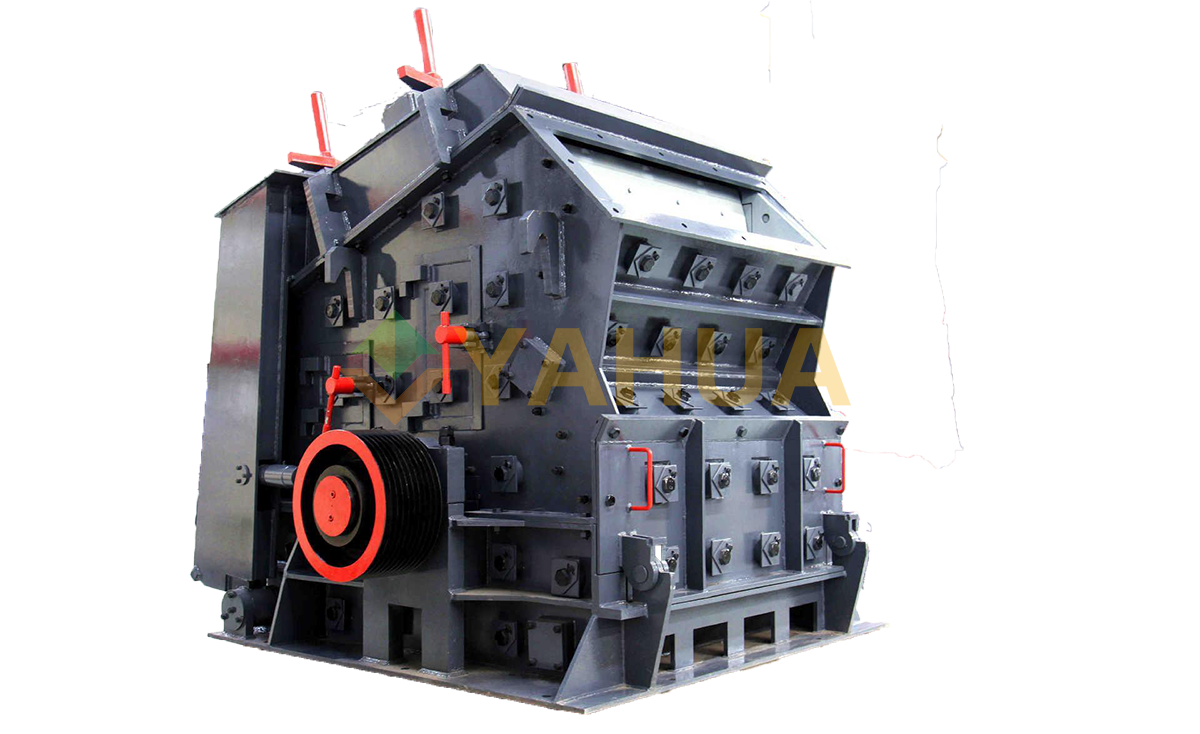

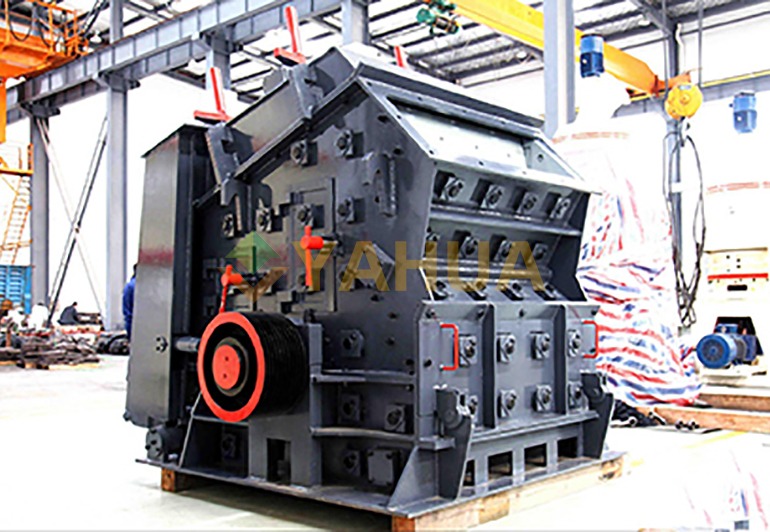

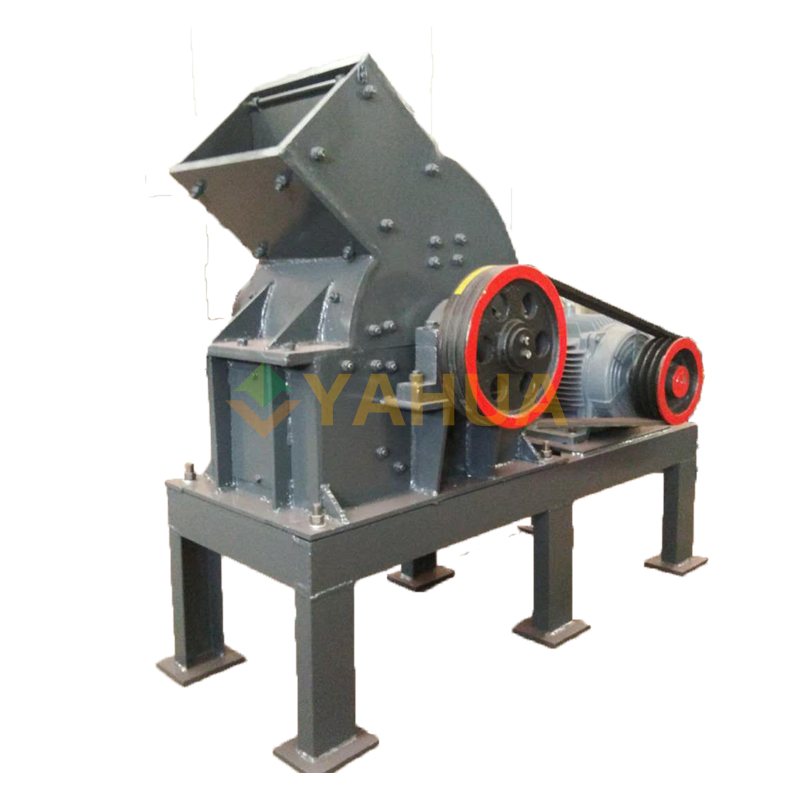

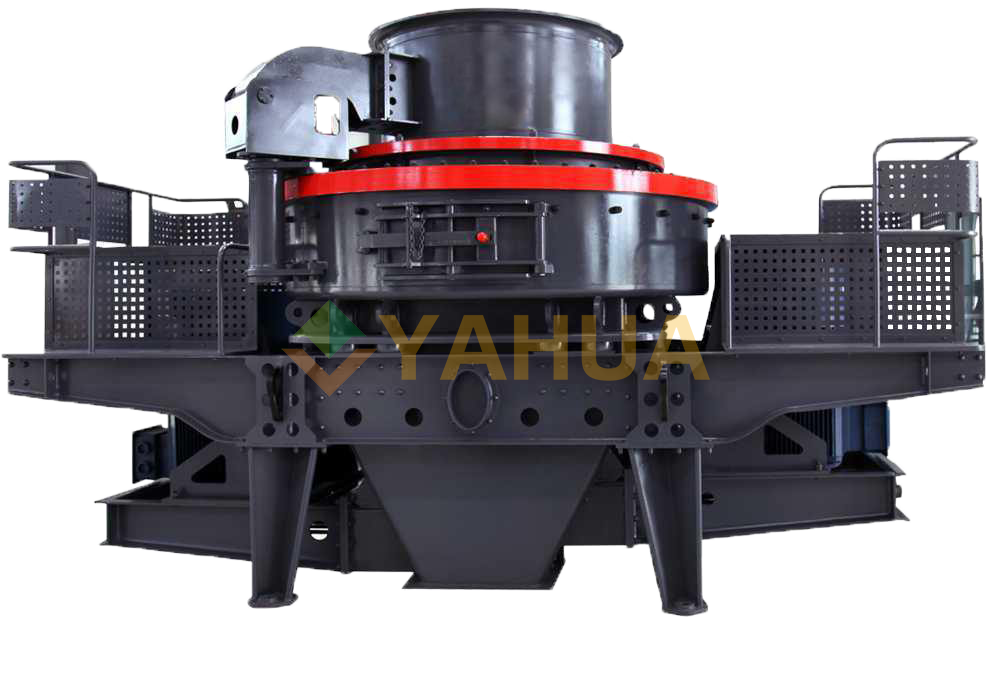

Impact crusher is suitable for crushing various ores, slag, concrete and other medium and high hardness brittle materials. Because of its large crushing ratio, high content of cubic particles in the product and large specific surface area, it is widely used in medium and fine crushing and fine crushing operations in metallurgy, mining, chemical industry, cement, construction, refractory materials and ceramics industries.

【Capacity】:50-220T/h

【Feeding size】:250-500mm

【Power】:4-300kw

Application Areas:

Industrial sectors such as metallurgy, mining, cement, chemicals, refractory materials and ceramics, as well as highway construction, water conservancy projects, building gravel, machine-made sand processing and other fields. (For more application areas, please click "Free Consultation")

Adaptable materials:

Suitable for medium and fine crushing of various soft and medium hard ores, such as limestone, feldspar, calcite, talc, barite, fluorite, rare earth, kaolin, coke, gangue, gypsum, etc.

Equipment Features:

1.High efficiency and energy saving, wear-resistant and pressure-resistant

The machine has a large crushing ratio, high crushing efficiency, a large rotor moment of inertia, and low energy consumption; it uses high-chromium plate hammers, which are impact-resistant and wear-resistant, effectively extending the service life of wearing parts.

2.Simple structure, easy maintenance

The machine has a simple structure, mainly consisting of a housing, a rotor and a counter-attack plate. The frame can be quickly opened through the lifting device to replace and repair the machine parts; the rotor and the main shaft are connected by a keyless expansion sleeve, which is convenient for maintenance, economical and reliable.

3.The particle size of the material can be adjusted and the particle shape is good

The top of the machine is equipped with a discharge port adjustment device, which can quickly and easily adjust the gap between the impact plate and the hammer to control the discharge size; the finished product is in a cubic shape, without tension cracks, with good particle shape, and meets the grade standards of various sand and gravel aggregates.

Working Principle

This series of products use impact energy to crush materials. When working, the rotor rotates at high speed driven by the motor, and the materials entering from the feed port collide with the plate hammer on the rotor, and are crushed by the high-speed impact of the plate hammer; the crushed materials are impacted onto the lining plate and crushed again; and finally discharged from the discharge port. The gap between the impact frame and the rotor frame can be adjusted to achieve the purpose of changing the material discharge particle size and shape.