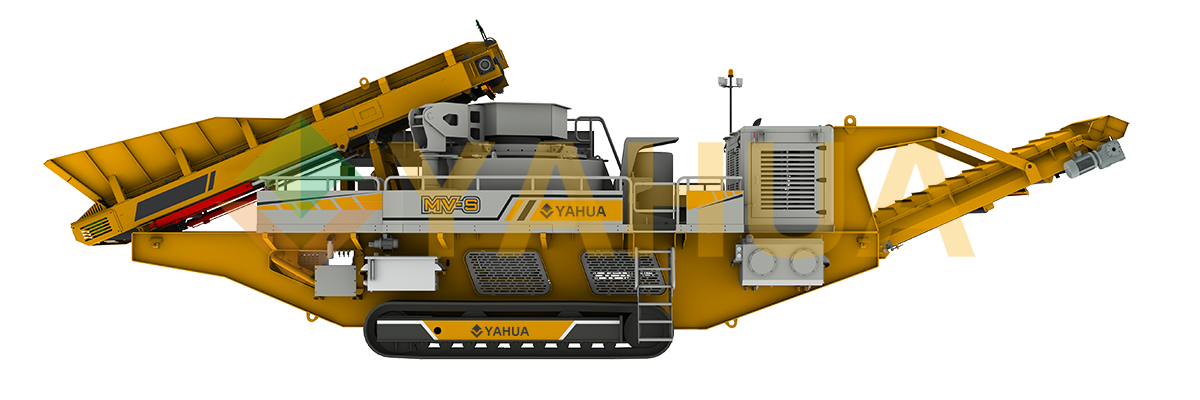

Wheel sand washer is a high-efficiency sand washing equipment developed and produced by our company using advanced domestic and foreign technologies and combining the actual situation of the domestic sand and gravel industry for use with sand making machines.

【capacity】:40—300t/h

【input size】:≤10mm

【power】:7.5-18.5kw

Application :

washing, grading, impurity removal and other operations in metallurgy, building materials and other industries.

Applicable materials:

Copper ore, cement, quartz sand, refractory materials, concrete aggregates.

Features:

1. Large processing capacity and low production cost

The output of a single machine can reach up to 180 tons/hour, which basically meets the sand washing needs of customers; the machine has low investment, low power, low electricity consumption, and effectively saves production costs.

2. Multiple functions and high cleaning degree

The equipment has two functions: cleaning, dehydration; when working, driven by the impeller, the sand and gravel grind each other to remove impurities covering the surface of the sand and gravel, while destroying the water vapor layer covering the sand particles, and completing the cleaning and impurity removal function in the strong water flow.

3. Simple structure and low failure rate

The sand washer has a simple and reasonable structure. The impeller drive bearing device is isolated from water and water-receiving materials, the novel sealing structure, and the fully enclosed oil bath transmission device greatly avoid the phenomenon of bearing damage caused by immersion in water, sand and pollutants.

4. Long service life and no pollution

The good structural layout and effective sealing design enable the machine to be durable and long-term without maintenance; low water consumption, low working noise, and meet national environmental protection standards.

5. Compared with traditional sand washing machines

The wheel sand washer has high cleaning degree, reasonable structure layout, large processing capacity and low power consumption. Its series of characteristics prove that it will be the choice for upgrading the domestic sand washing industry.

Working Principle

During operation, the motor drives the impeller to rotate slowly after deceleration through the V-belt, reducer, and gear. The sand and gravel enter the washing tank from the feeding tank, roll under the drive of the impeller, and grind each other to remove impurities covering the surface of the sand and gravel, and at the same time destroy the water vapor layer covering the sand particles to facilitate dehydration; at the same time, water is added to form a strong water flow, which promptly takes away impurities and foreign objects with small specific gravity, and discharges them from the overflow outlet of the washing tank to complete the cleaning effect. The clean sand and gravel are taken away by the blades, and finally the sand and gravel are poured into the discharge tank from the rotating impeller to complete the cleaning effect of the sand and gravel.