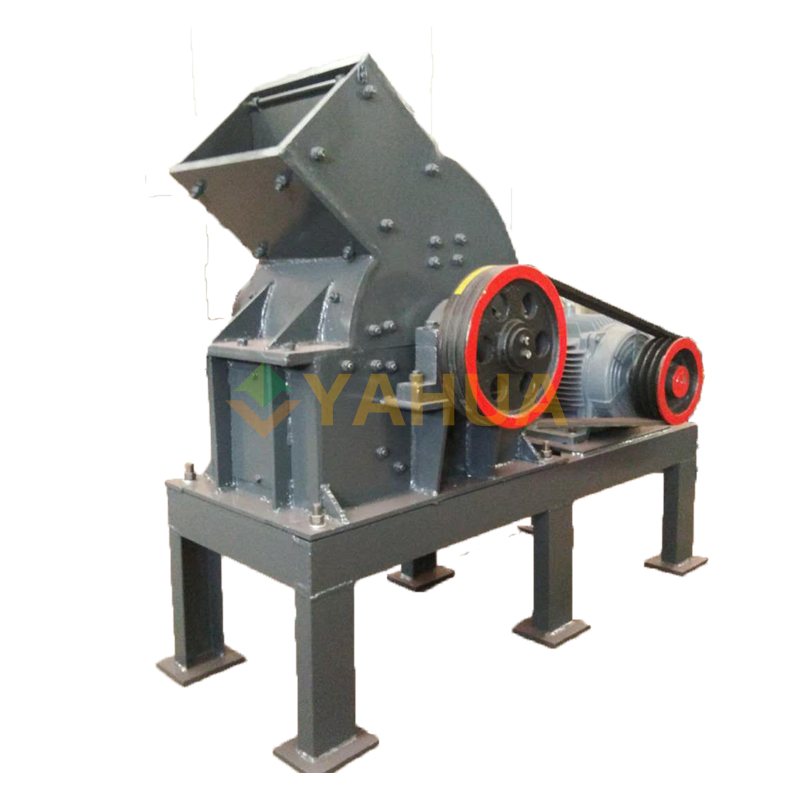

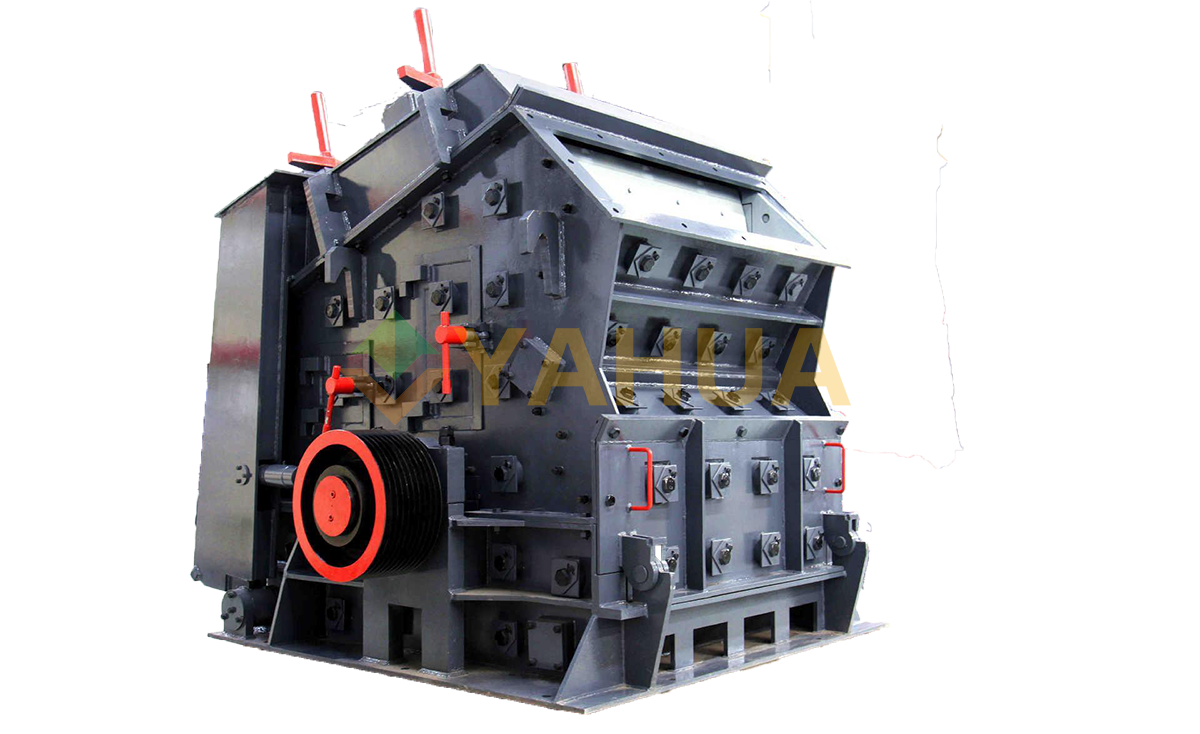

Hammer crusher is a crusher that directly crushes materials with a maximum particle size of 600-1800 mm to 25 or less mm. Hammer crusher is suitable for medium and fine crushing of materials with medium hardness, such as limestone, slag, coke, coal, etc. in cement, chemical, electric power, metallurgy and other industrial sectors.

【Capacity】:3-30(t/h)

【Feeding size】:100-300(mm)

【Output size】:≤35(mm)

Application :

Used for crushing brittle materials with medium hardness and ore compressive strength not exceeding 120Mpa.

Adaptable materials:

Coal, limestone, gypsum, soft refractory materials

Equipment Features:

Strong applicability

Large crushing ratio, high production efficiency, strong applicability, and the required particle size can be adjusted according to customer requirements.

High efficiency and environmental protection

There is no screen grate bottom, and there is no requirement for the moisture content of the material. There is absolutely no problem of clogging the screen plate, and there is no problem of material not being discharged in time and repeated crushing. The hammer crusher body structure is sealed, which solves the dust pollution and ash leakage problems in the crushing workshop.

Simple structure

The overall design is beautiful, the structure is compact, there are few wearing parts, and it is easy to maintain. It is an upgraded product.

Advanced technology

The bearing boxes are all made of cast steel and fixed with four screws, which is scientific and practical; the working hammer head is cast with new technology and is wear-resistant and impact-resistant.

Working Principle

The hammer crusher is mainly composed of the casing, rotor, hammer iron and grate bars. The casing is divided into two parts, which are welded after cutting steel plates, and the other parts are connected into one with bolts. The casing is inlaid with high manganese steel lining, which can be replaced after wear. The hammer crusher main shaft is equipped with a regular array of hammers, which together with the turntable and hammer shaft form the rotor.

The main shaft is driven by the motor and the V-belt to rotate the rotor. The hammers are extended to the surroundings by the centrifugal force generated by the rotation. After the large pieces of material enter the crushing chamber from the feed port, they are crushed by the high-speed moving hammers. The qualified crushed materials are discharged by the grate bars with gaps at the bottom, and the unqualified ones remain in the crushing chamber and are repeatedly acted on by the hammers and hammer iron blocks until they can be discharged.