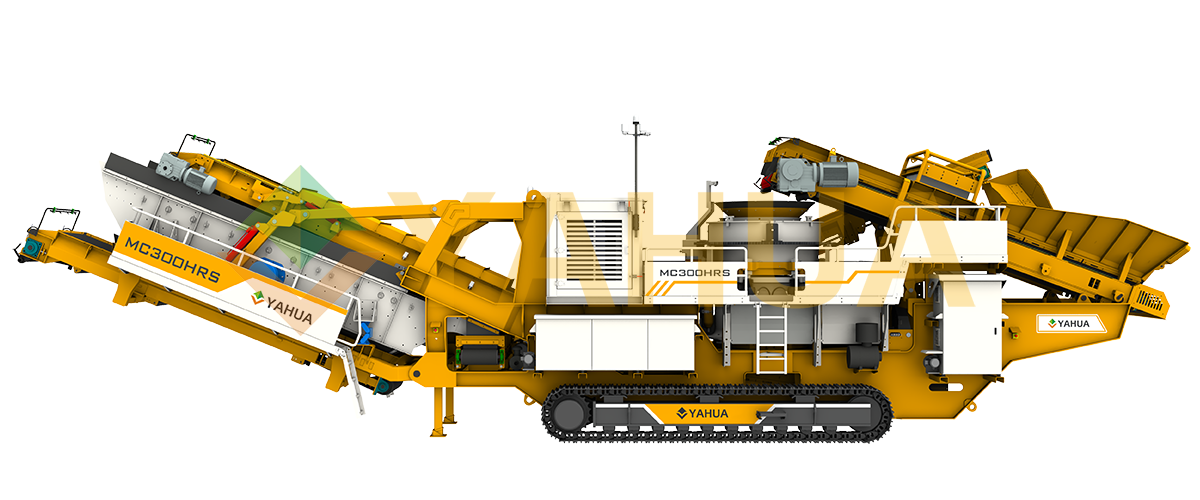

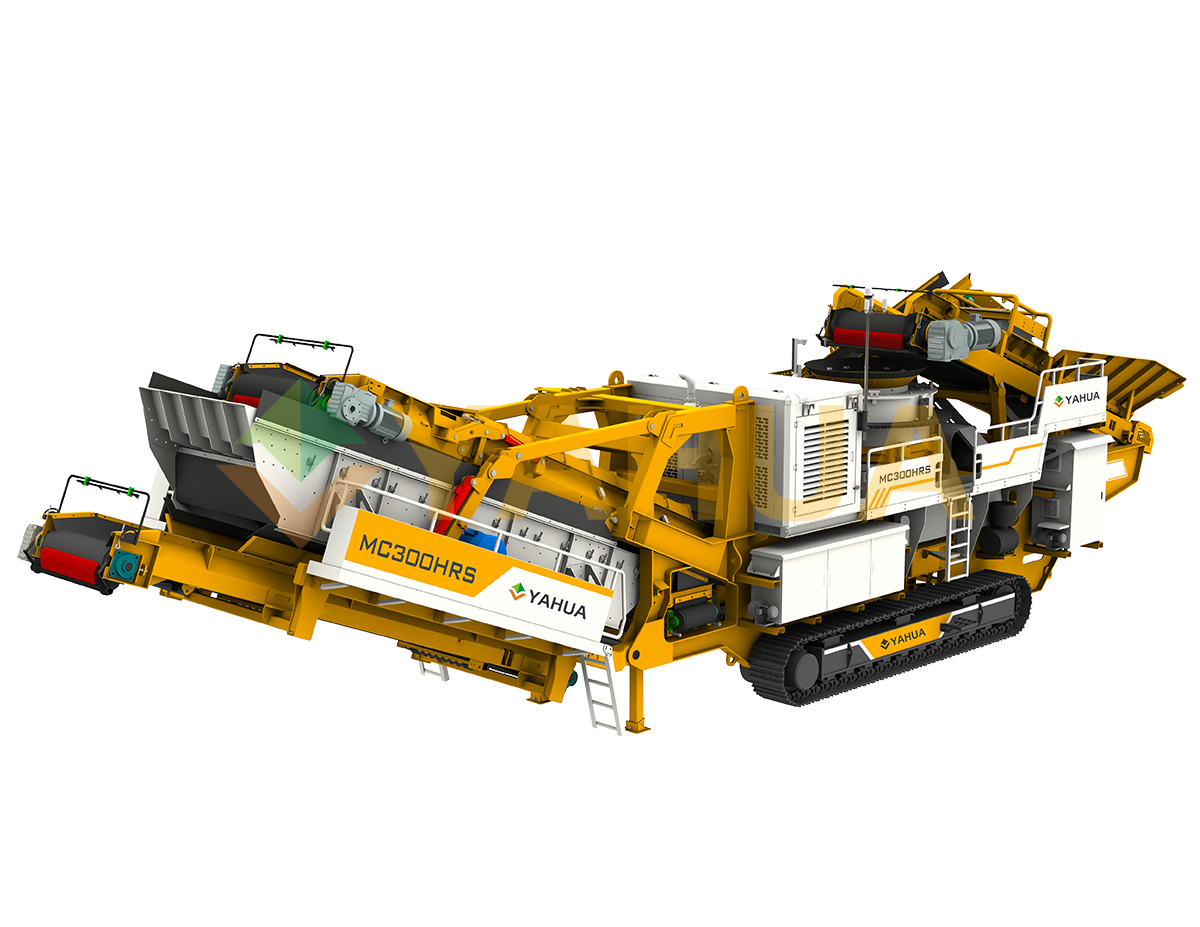

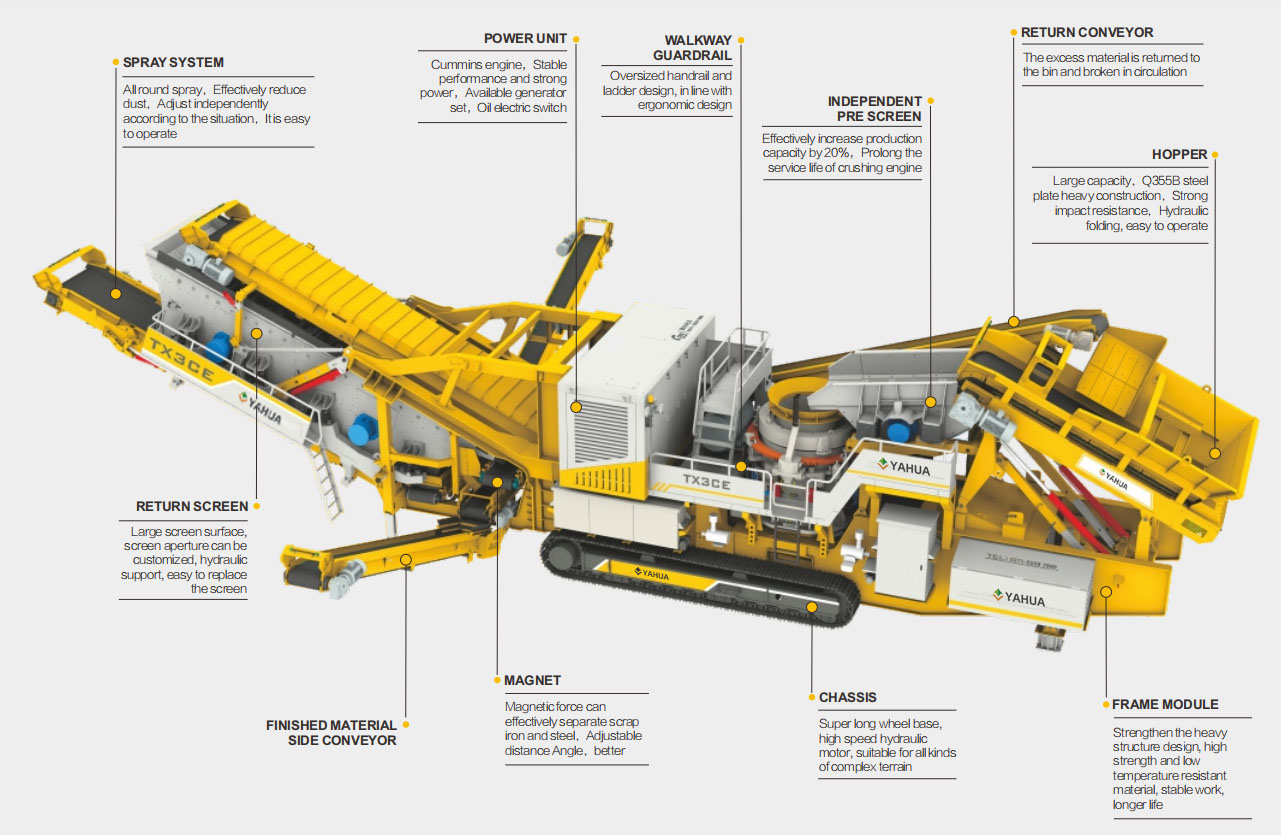

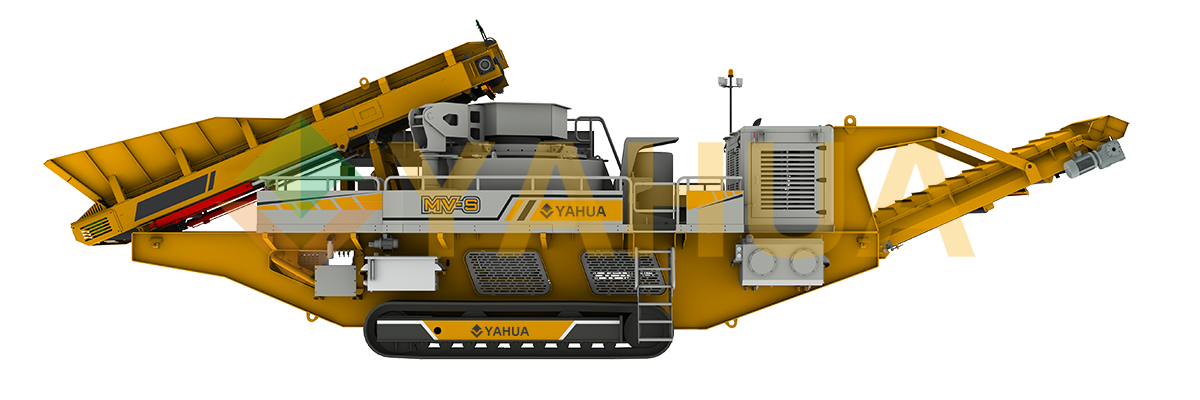

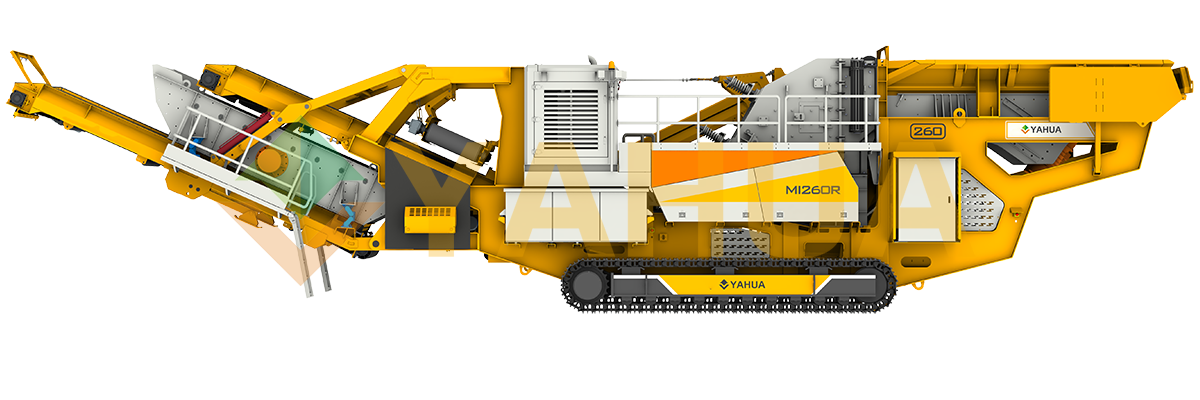

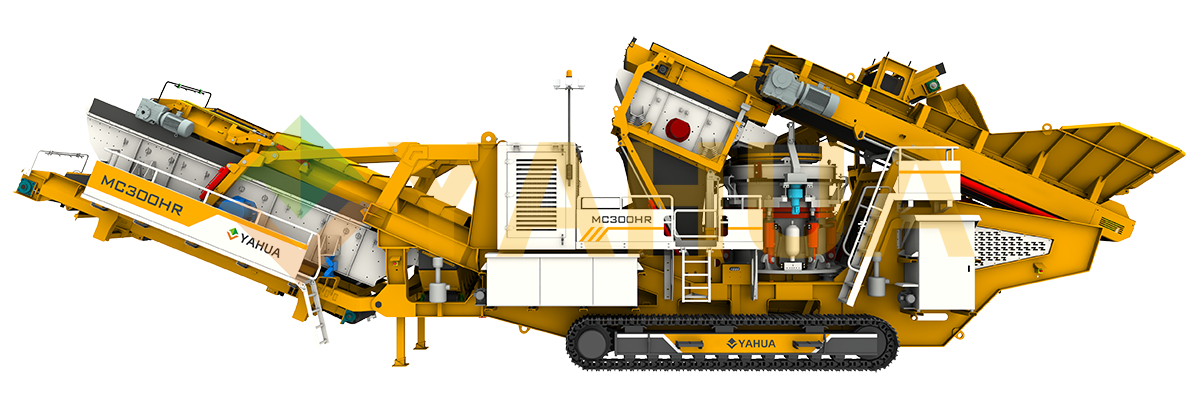

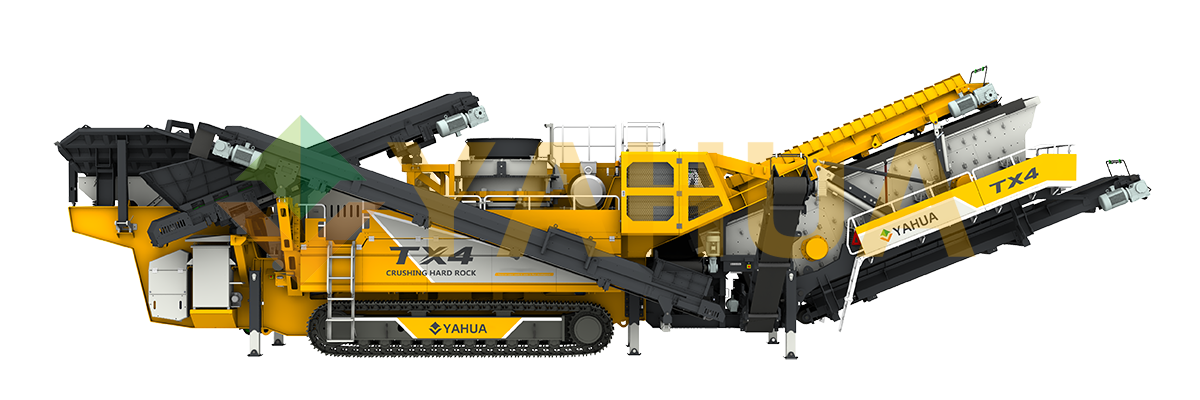

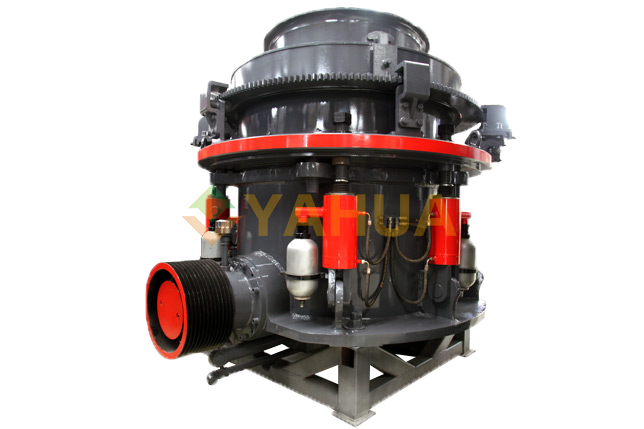

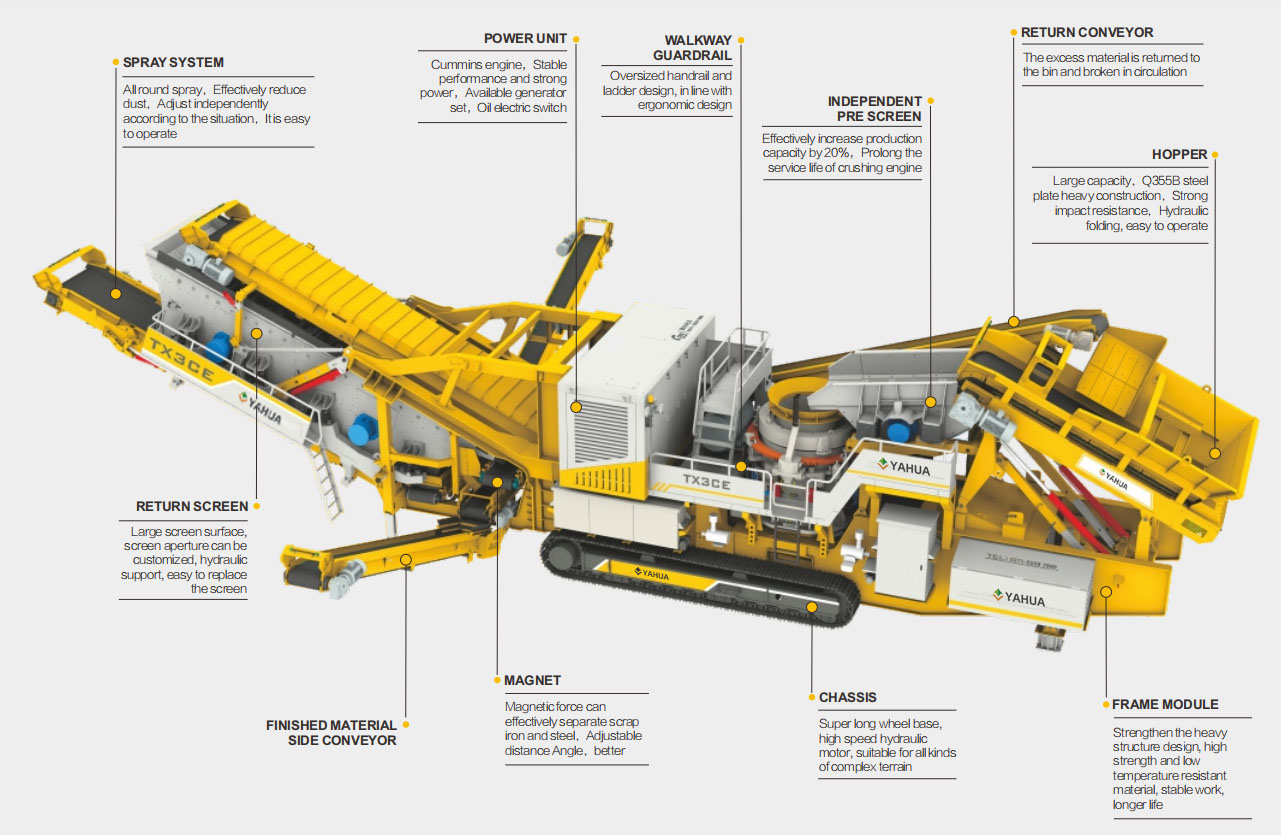

Tracked mobile cone crushing and screening integrated machine, one machine realizes two processes of crushing and screening, simplifying the process flow. Not only does it integrate three core units: feeder, cone crusher, and three-layer double stage screen, achieving the screening effect of a split production line, but it is also equipped with an independent pre screening device, further improving the crushing efficiency.

The whole machine has a wide range of applications, high intelligence, simpler operation, convenient transfer, high crushing efficiency, and can choose from three power modes: external power supply, hybrid oil and electricity, and full hydraulic drive.