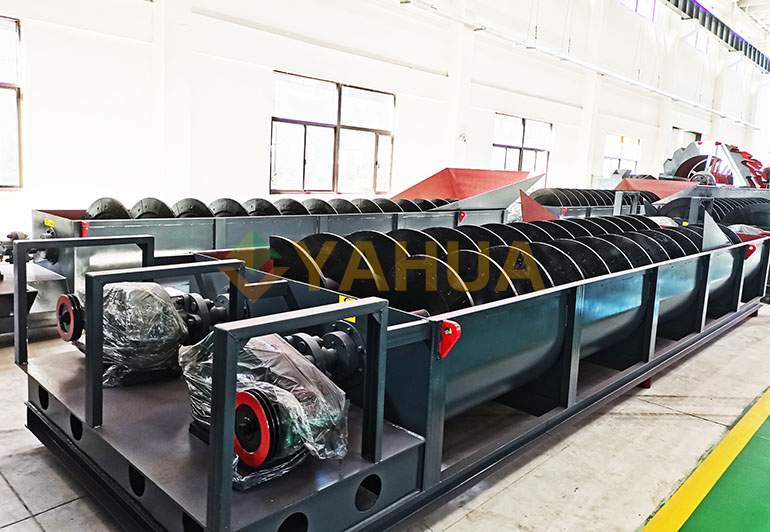

Spiral sand washer is suitable for washing, grading, impurity removal and other operations in metallurgy, building materials and other industries. It is used for washing fine and coarse materials. It is especially suitable for construction sand and road sand. Spiral sand washer has low power consumption, high cleaning degree, good sealing structure, fully enclosed transmission device, adjustable weir plate, which ensures the product is efficient and durable, with good cleaning and dehydration effects, and the fine grain product remains stable.

【capacity】:100-350t/h

【Input size】:≤10mm

【Power】:11-37kw

Application :

washing, grading, impurity removal and other operations in metallurgy, building materials and other industries.

Applicable materials:

Copper ore, cement, quartz sand, refractory materials, concrete aggregates.

Features:

1. New design, more stable

The novel sealing structure, fully enclosed oil bath transmission device, and adjustable overflow weir plate ensure that this series of products are efficient, durable, have good cleaning and dehydration effects, and maintain stable fine grain products.

2. Stable operation, safe and reliable

Simple structure, stable operation, safe and reliable, very little loss of medium and fine sand, and the grading and fineness modulus of the washed construction sand meet the national "Construction Sand" standard;

3. Reasonable structure and high efficiency

The spiral sand washer has a reasonable structure, convenient maintenance, large processing capacity, low power consumption, and high cleaning degree.

4. Low loss rate

The optimized spiral blades ensure that the loss of wearing parts is minimized.

Working Principle

The spiral sand washer has a reasonable structure, convenient maintenance, large processing capacity, low power consumption and high cleaning degree. The novel sealing structure, fully enclosed oil bath transmission device and adjustable overflow weir plate of the spiral sand washer ensure that this series of products are efficient, durable, have good cleaning and dehydration effects, and keep fine particles neat.