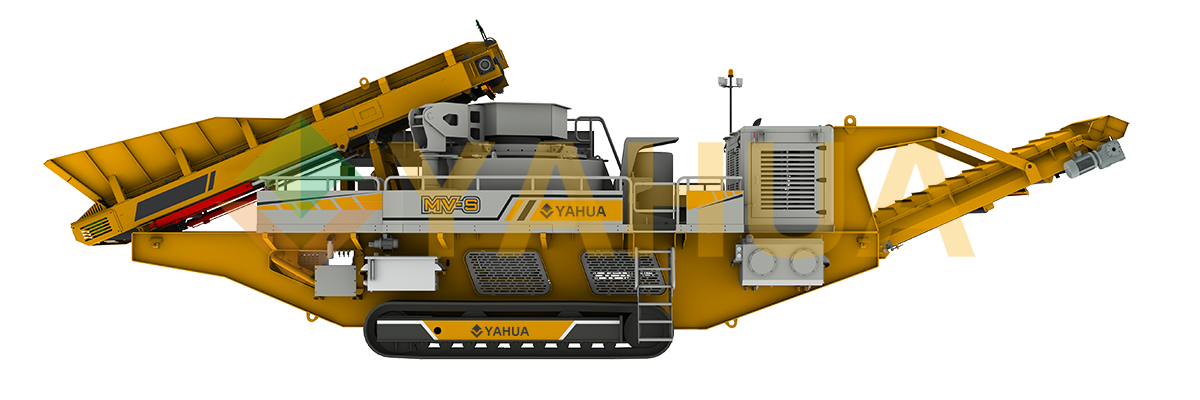

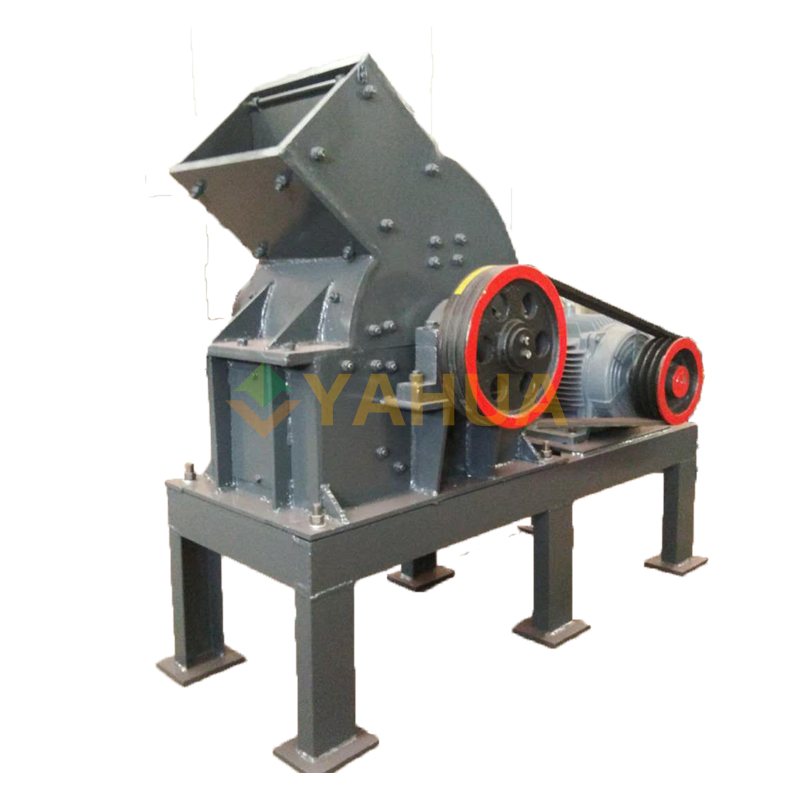

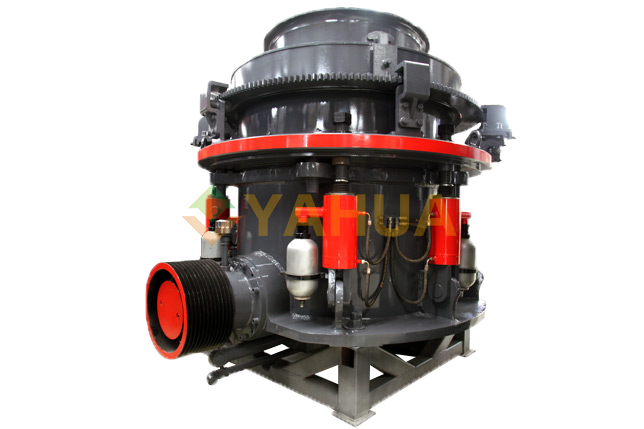

GP single-cylinder hydraulic cone crusher widely absorbs advanced crusher technologies from the United States, Germany and other countries, with a new crusher structure, combined with an optimized laminated crushing chamber and a fully intelligent automatic control system. GP series single-cylinder hydraulic cone crusher has incomparable performance characteristics of traditional cone crushers. It can be widely used in medium crushing, fine crushing and ultra-fine crushing operations. It is a new type of high-efficiency crusher independently developed and designed. The cone crusher integrates mechanical, hydraulic, electrical, automation and intelligent control technologies, representing the world's advanced crusher technology.

【Capacity】:30-2500t/h

【Feeding size】:≤600mm

【Output size】:8-75mm

Application Areas:

Sand and gravel yards, mining, coal mining, concrete mixing stations, dry mortar, power plant desulfurization, quartz sand, etc.

Adaptable materials:

River pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, etc.

Features:

1. High-quality stone: The hydraulic cone crusher adopts a unique crushing chamber shape and a lamination crushing principle to produce a crushing effect between particles, so that the proportion of cubes in the finished product is significantly increased, the needle-like stones are reduced, and the particle size is more uniform.

2、The hydraulic and lubrication systems with double insurance control can ensure the overload protection and good bearing lubrication of the machine.

Working Principle

When the single-cylinder cone crusher is working: the motor drives the small gear of the crusher, the small gear drives the large gear, the large gear assembly (large gear, large gear frame, eccentric steel sleeve) drives the eccentric sleeve assembly (eccentric cylinder sleeve, eccentric copper sleeve) and the main shaft assembly (main shaft, inner cone, inner cone liner) to revolve in the copper sleeve with the theoretical vertical line as the center, and the main shaft assembly can realize self-rotation in the eccentric copper sleeve with the center line of the main shaft. When the machine is running empty, the eccentric sleeve assembly "holds" the main shaft assembly and revolves with the large gear. When the material is added to the crushing chamber, the main shaft assembly (main shaft, inner cone) slowly rotates in the eccentric copper sleeve under the resistance of the material. The running track of the inner cone seems to swing back and forth in the crushing chamber, while rotating slowly. The material is squeezed and crushed by the swinging inner cone. The connection between the support sleeve and the frame is tightened by the hydraulic cylinder. When uncrushable objects such as metal blocks fall into the crusher, the moving cone of the single cylinder is lifted up by the bottom hydraulic piston to adjust the discharge port, protect against iron overload, and repeatedly rise and fall to eliminate blockage.