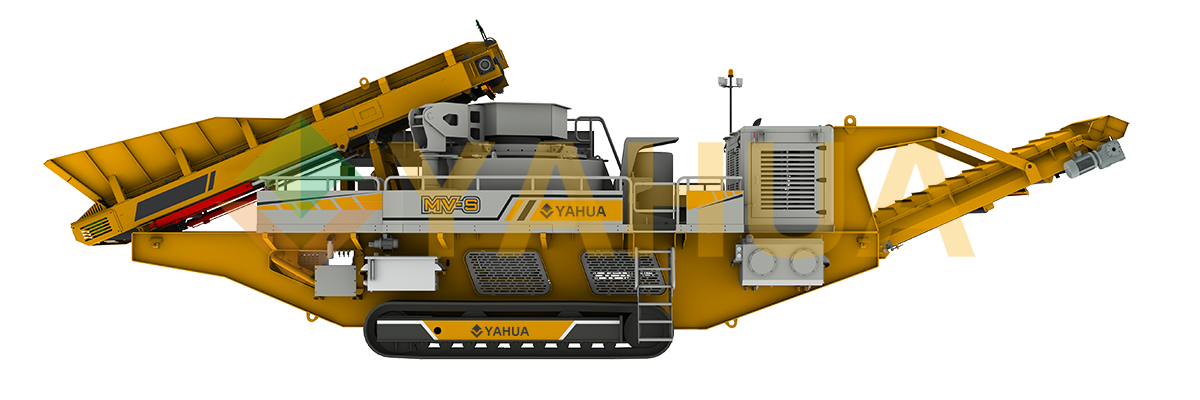

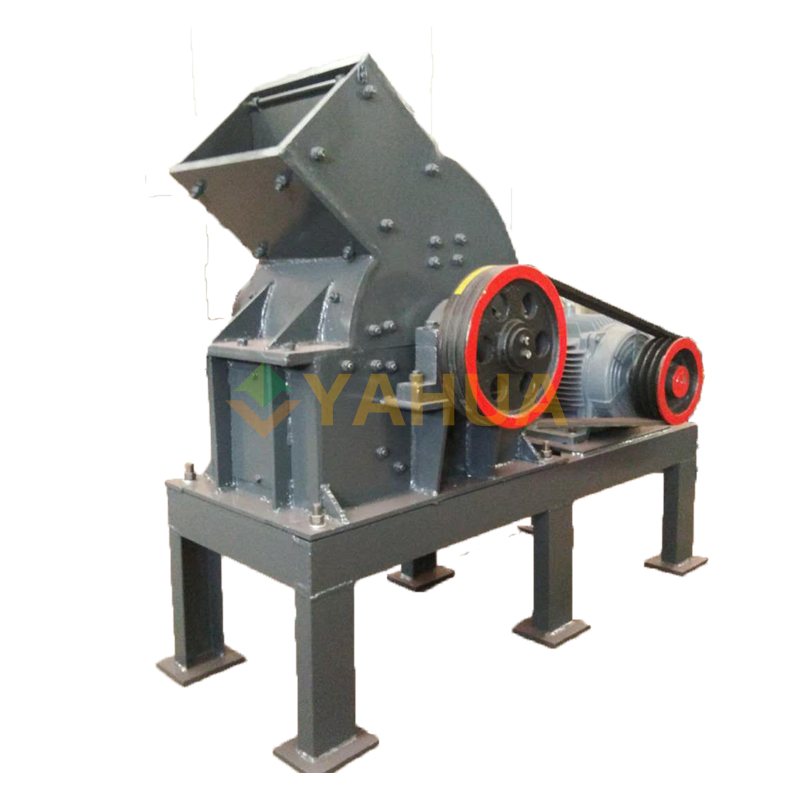

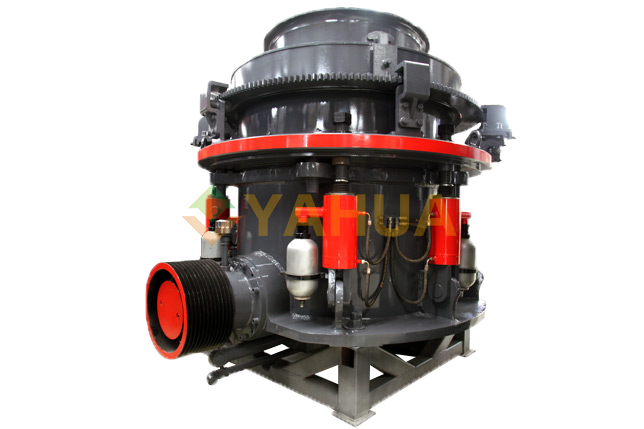

Spring cone crusher is suitable for crushing raw materials in metallurgy, construction, road construction, chemical and silicate industries. According to different crushing principles and different product particle sizes, it is divided into many models. Crusher is widely used in many departments such as mining, smelting, building materials, highways, railways, water conservancy and chemical industries. Cone crusher has large crushing ratio, high efficiency, low energy consumption, uniform product particle size, suitable for medium and fine crushing of various ores, rocks

【Capacity】:12-1000t/h

【Feeding size】:35-300mm

【Output size】:12-60mm

Application Areas:

Spring cone crusher is suitable for crushing raw materials in metallurgy, construction, road construction, chemical and silicate industries. It can crush various ores and rocks with medium and above medium hardness.

Adaptable materials:

Granite, talc, coal mud, limestone, alum stone and other materials.

Features:

1. Long service life

The equipment adopts full hydraulic operation, so it is easy to use, has strong iron-passing capacity, is easy to automate, and its reliability and life are greatly improved. In addition, the crusher can be automatically controlled by computer according to user needs, and even remote control

2.Easy maintenance

Due to the reasonable structural design of the spring cone crusher, all components are protected by wear-resistant parts to reduce maintenance costs, and all parts can be disassembled and maintained from the top or side, without disassembling the frame and tightening bolts, making daily maintenance of the equipment easier.

3.Excellent product quality

The spring cone crusher adopts a unique inter-granular lamination crushing effect, which makes the crushed materials more uniform and the product shape more neat; and the crushing chamber of the equipment is too deep, so that the material can be fully crushed in the chamber to achieve high-quality granular shape.

4.Higher processing power

The spring cone crusher combines a higher speed stroke, which increases the rated power and through-capacity of the spring cone crusher, greatly improves the processing capacity of the equipment, and increases production.

Working Principle:

During operation, the spring cone crusher motor rotates through the pulley or coupling, the cone crusher drive shaft and the cone crusher, and the eccentric sleeve forces the cone to swing around a fixed point. This causes the crushing wall of the crushing cone to sometimes approach and sometimes leave the surface of the mortar wall fixed on the adjustment sleeve, so that the ore is continuously impacted, squeezed and bent in the crushing chamber to achieve ore crushing.