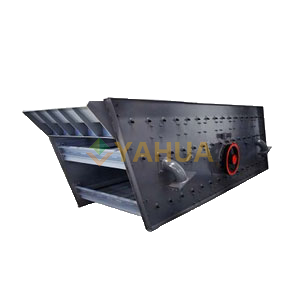

YZS vibrating screen is a new type of screening equipment, with a circular vibration trajectory. It is specially designed for screening stone in quarries, and can also be used for product classification in coal preparation, mineral processing, building materials, electricity and chemical industries. The vibrating screen has the characteristics of advanced structure, strong excitation force, low vibration noise, easy maintenance, and durability.

【Input Size】:≤200MM

【Capacity】:15—600t/h

Application:

Suitable for screening sand and gravel in quarries, and can also be used for product grading in industries such as coal preparation, mining, ore dressing, building materials, electricity and chemical industry.

Applicable materials: granite, basalt, shale, quartz, river pebbles, limestone, iron ore, coal, non-ferrous metal ore, pebbles, etc.

Features:

1. Novel structure and large processing capacity

The vibrating screen has a novel structure, advanced technology, large processing capacity and high screening efficiency;

2. Long service life

The YZS vibrating screen adopts spring steel woven screen or punched screen plate, which has a long service life and is not easy to block holes;

3. Convenient to use and easy to maintain

The YZS vibrating screen adopts a cylindrical eccentric shaft exciter and an eccentric block to adjust the amplitude, which is convenient to use and maintain;

4. Low noise and stable operation

The YZS vibrating screen adopts rubber vibration isolation springs, which have long service life, low noise, and stable over-resonance area.

Working Principle

The YZS vibrating screen mainly consists of a screen box, a screen mesh, a vibrator, a vibration damping spring device, a chassis, etc. The side panels of the screen machine are made of high-quality steel plates, and the side panels are connected to the crossbeam and the base of the exciter with high-strength bolts or ring groove rivets. The cylindrical eccentric shaft exciter and the eccentric block are used to adjust the amplitude. The vibrator is installed on the side panel of the screen box, and is driven by the motor through the V-belt to make the eccentric block of the exciter rotate at high speed, generating a large centrifugal inertia force, which excites the screen box to produce a circular motion of a certain amplitude. The material on the screen is subjected to the impulse transmitted by the screen box on the inclined screen surface, and a continuous throwing motion is produced. In the process of the material meeting the screen surface, the particles smaller than the screen hole are screened, thereby achieving classification.