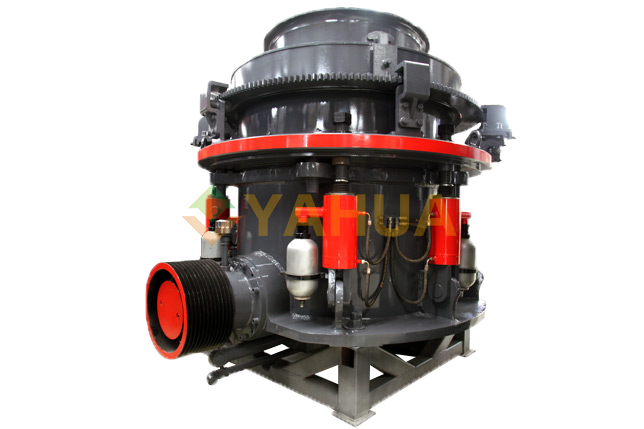

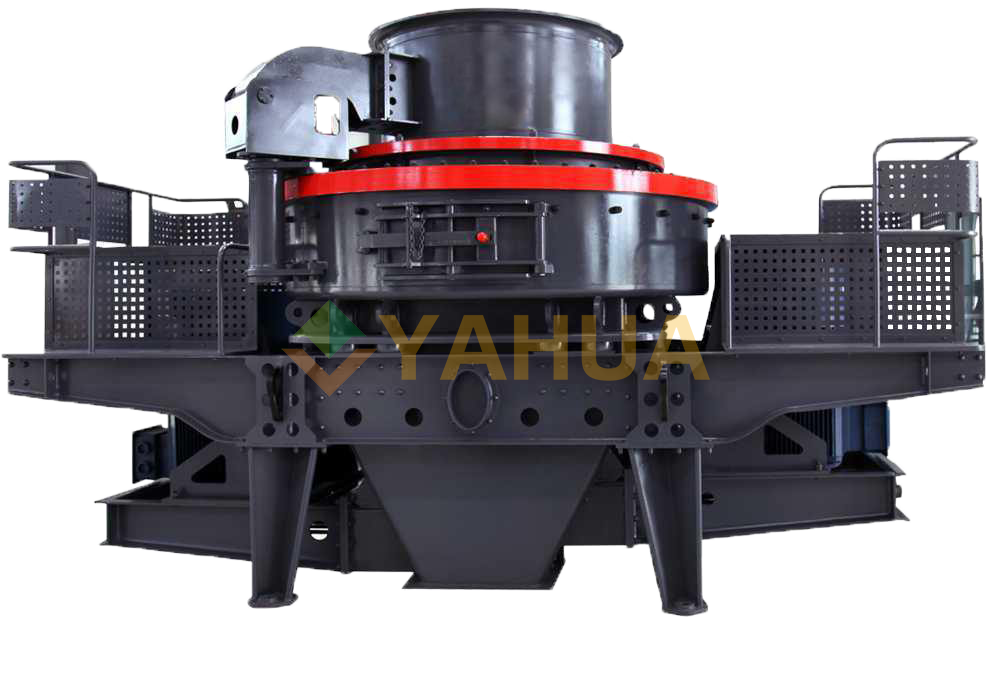

HP Hydraulic cone crusher is a high-efficiency crusher independently developed by our company with the introduction of American technology, combined with international cutting-edge alloy materials and mechanical manufacturing processes. It is particularly suitable for crushing chrome ore, basalt, granite and other medium-to-high hardness brittle materials, and is widely used in medium and fine crushing and fine crushing operations in metallurgy, mining, chemical industry, cement, construction, refractory materials and ceramics industries.

【Capacity】:55-610(t/h)

【Feeding size】:76-320(mm)

【Output size】:6-38(mm)

Application Areas:

Widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy and chemical industries

Adaptable materials:

Rocks, ores, slag, refractory materials, etc.

Features:

1.High capacity

The combination of higher speed and stroke greatly increases the rated power and throughput of the HP cone crusher, improving the crushing ratio and production efficiency.

2.Strong adaptability

The HP cone crusher only needs to replace the fixed cone liner plate, the moving cone liner plate, and the crushing chamber shape can be freely changed from the standard ultra coarse chamber type to the short head ultra fine chamber type, adapting to a wide range of product particle size requirements

3.Excellent particle shape of the finished product

The combination of higher speed and stroke greatly increases the rated power and throughput of the HP crusher, improving the crushing ratio and production efficiency.

4.Simple operation and maintenance

All parts of the HP cone crusher can be disassembled and maintained from the top or side. The movable cone and fixed cone are easy to disassemble and assemble, without disassembling the frame or tightening bolts. Therefore, it is more convenient to replace the liner of the HP cone crusher on a daily basis. The use of hydraulic motor maximizes the production efficiency of the crusher.

5.Low operating costs

Reasonable structure, advanced crushing principle and technical parameters, reliable operation, low operating cost; all parts of the crusher are wear-resistant, which reduces maintenance costs to a minimum and generally increases service life by more than 30%. It is mainly used in large stone factories to solve the shortcomings of impact crushers, such as small average crushing ratio, high energy consumption, and rapid wear of hammer heads, impact plates, and linings.

6.High degree of automation

The hydraulic adjustment of the discharge port and overload protection greatly improve the operation level of the crusher, making maintenance simpler, operation more convenient and downtime shorter; the HP series cone crusher's two-way iron release hydraulic cylinder can allow iron blocks to pass through the crushing chamber. In the event of iron overload and instantaneous jamming, the machine can hydraulically lift the top and automatically discharge, greatly reducing the trouble of the original spring cone crusher needing to stop for manual discharge, while many other manufacturers' crushers will stop due to iron jamming.

Working Principle:

The working process is to drive the pulley or coupling, transmission shaft and cone part to make the eccentric shaft do periodic swing motion under the axis line through the rotation of the motor. After the material enters the crushing chamber from the material inlet, it is crushed by the mutual impact, extrusion, grinding and kneading of the eccentric shaft and the mortar wall. The hydraulic safety system can remove the faulty objects from the support sleeve and the top of the fixed cone part through hydraulic pressure when the machine has an iron fault or a jamming phenomenon, which greatly reduces the maintenance rate and improves production efficiency while playing a good insurance role.